Brooklyn Hospital Coil Section Retrofit / 2025-11-06 /

Brooklyn Hospital Coil Section Retrofit / 2025-11-06 /

Nov 6, 2025

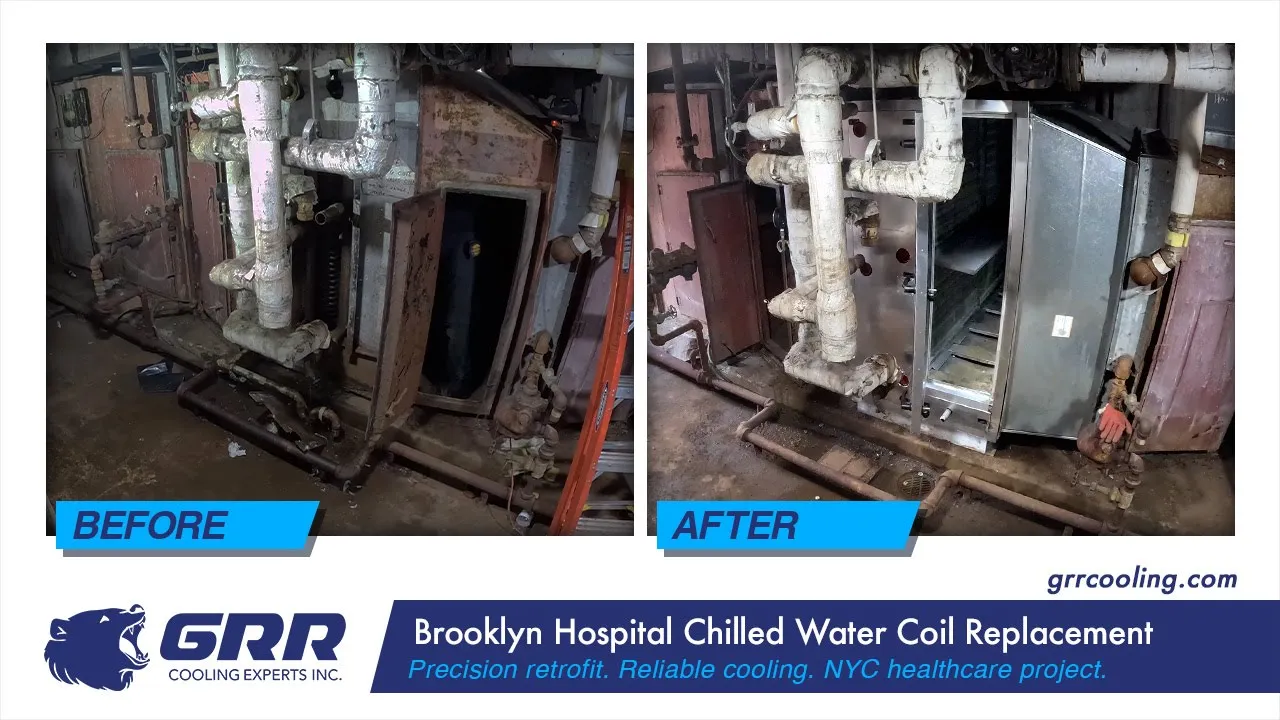

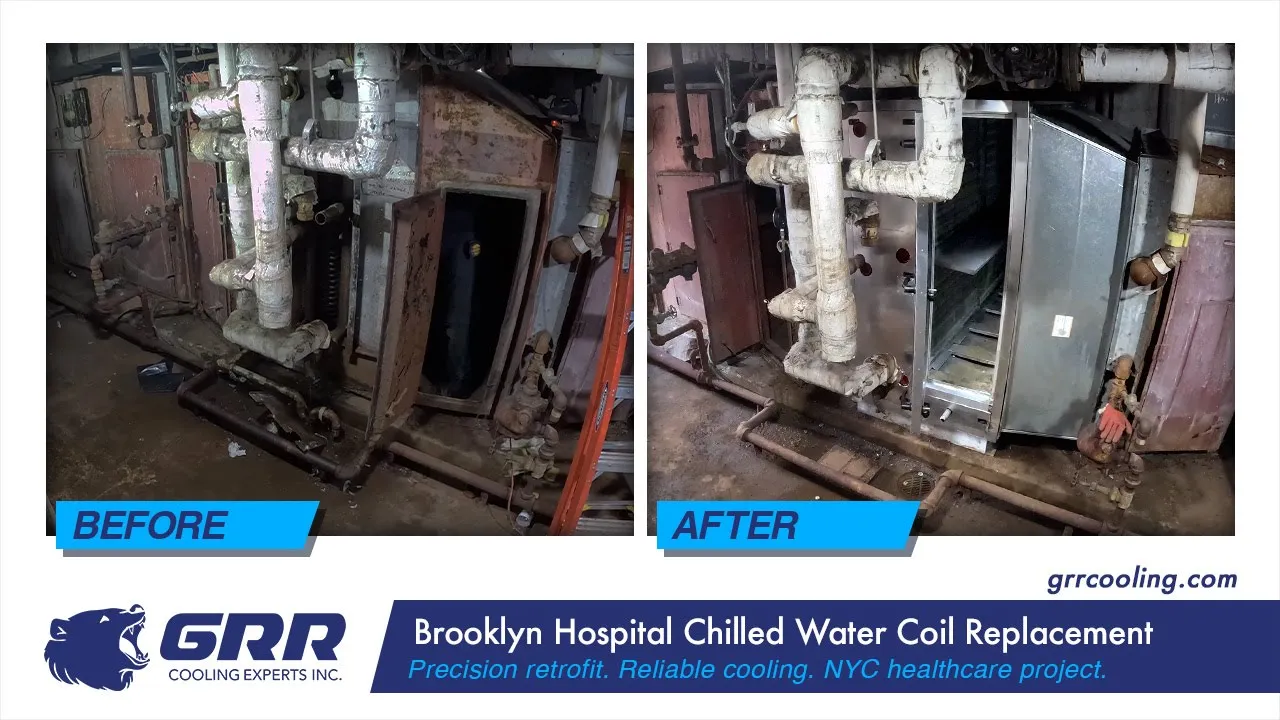

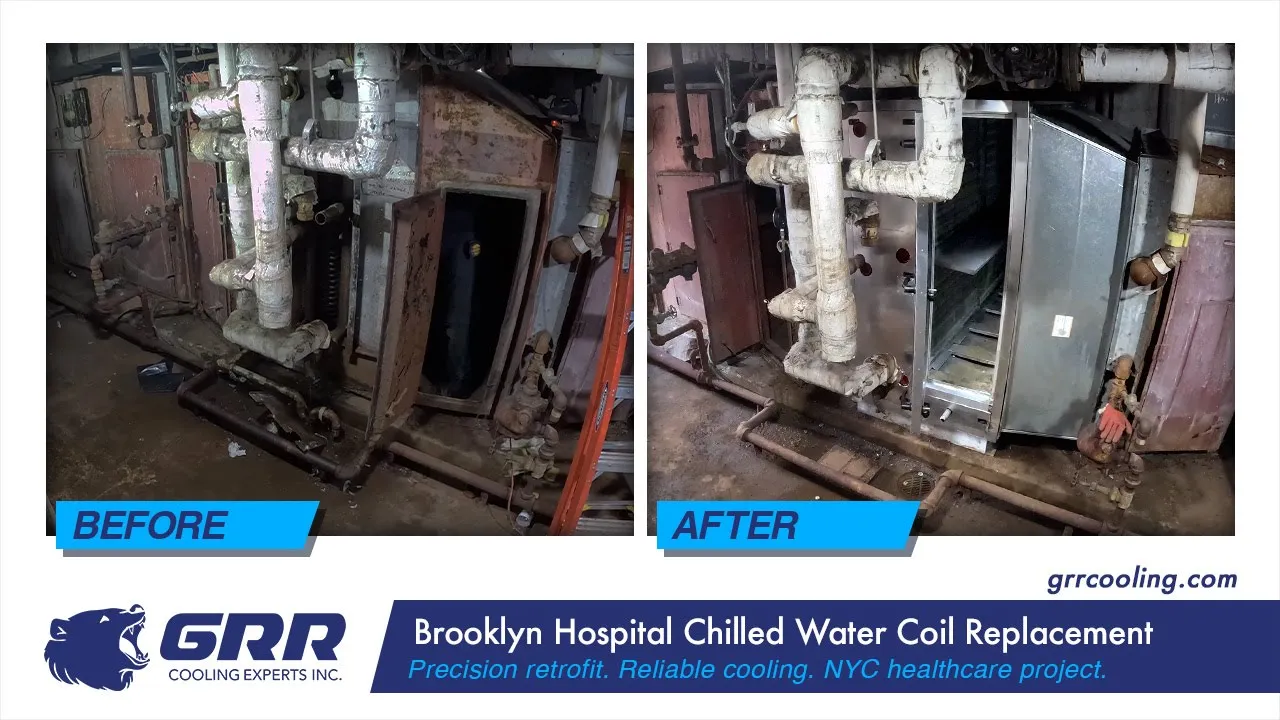

Design: dual-coil aluminum section with condensate and chilled-water piping integration.

The upgrade restores cooling performance and reliability with zero disruption to hospital operations.

On November 6, our field crew completed another live retrofit at The Brooklyn Hospital Center, fabricating and installing a new chilled-water coil section between 8 AM and 2 PM — all within a single shift.

Time Highlights:

Phase 1 — Disconnected existing chilled-water piping, demolished and removed the old coil section.

Phase 2 — Fabricated and installed a new 2″ aluminum panel section with drip pan and intermediate framing.

Phase 3 — Installed two (2) new chilled-water coils, reconnected and insulated piping, and added a new condensate line.

System Specs:

🔹 Coil Section — Custom-fabricated aluminum frame with integrated drip pan

🔹 Coils — (2) high-efficiency chilled-water coils

🔹 Piping — Modified and reconnected chilled-water and condensate lines

🔹 Insulation — Full vapor-sealed insulation for energy efficiency and condensation control

🔹 Completion — 6 hours total on-site time (8 AM–2 PM) under live hospital conditions

𝗢𝘂𝘁𝗰𝗼𝗺𝗲:

The new chilled-water section delivers improved cooling efficiency, reliable temperature control, and extended coil lifespan.

Fabricated, installed, and commissioned in one day in partnership with BAIKAL MECHANICAL— ensuring uninterrupted comfort and system stability for hospital operations.

𝗚𝗥𝗥 𝗖𝗼𝗼𝗹𝗶𝗻𝗴 𝗘𝘅𝗽𝗲𝗿𝘁𝘀 — 𝗥𝗲𝗹𝗶𝗮𝗯𝗹𝗲 𝗔𝗶𝗿. 𝗘𝘃𝗲𝗿𝘆 𝗧𝗶𝗺𝗲.

——-

Watch the Video from the installation

Design: dual-coil aluminum section with condensate and chilled-water piping integration.

The upgrade restores cooling performance and reliability with zero disruption to hospital operations.

On November 6, our field crew completed another live retrofit at The Brooklyn Hospital Center, fabricating and installing a new chilled-water coil section between 8 AM and 2 PM — all within a single shift.

Time Highlights:

Phase 1 — Disconnected existing chilled-water piping, demolished and removed the old coil section.

Phase 2 — Fabricated and installed a new 2″ aluminum panel section with drip pan and intermediate framing.

Phase 3 — Installed two (2) new chilled-water coils, reconnected and insulated piping, and added a new condensate line.

System Specs:

🔹 Coil Section — Custom-fabricated aluminum frame with integrated drip pan

🔹 Coils — (2) high-efficiency chilled-water coils

🔹 Piping — Modified and reconnected chilled-water and condensate lines

🔹 Insulation — Full vapor-sealed insulation for energy efficiency and condensation control

🔹 Completion — 6 hours total on-site time (8 AM–2 PM) under live hospital conditions

𝗢𝘂𝘁𝗰𝗼𝗺𝗲:

The new chilled-water section delivers improved cooling efficiency, reliable temperature control, and extended coil lifespan.

Fabricated, installed, and commissioned in one day in partnership with BAIKAL MECHANICAL— ensuring uninterrupted comfort and system stability for hospital operations.

𝗚𝗥𝗥 𝗖𝗼𝗼𝗹𝗶𝗻𝗴 𝗘𝘅𝗽𝗲𝗿𝘁𝘀 — 𝗥𝗲𝗹𝗶𝗮𝗯𝗹𝗲 𝗔𝗶𝗿. 𝗘𝘃𝗲𝗿𝘆 𝗧𝗶𝗺𝗲.

——-

Watch the Video from the installation